SmartStripping a Parma

![]()

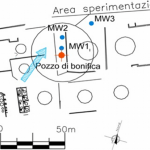

The site object of the field test is a depository of hydrocarbons located in the province of Parma. The first subsoil consists of alluvial soils with a prevalence of sands and gravels, where circulates a phreatic aquifer with an average thickness of about 6 m and water table depth of about 3,5 – 4 m below ground level. Groundwater at the site boundary were found contaminated by Metil-t-butil etere (MTBE), total hydrocarbons and total aromatic organic compounds, with concentrations of respectively 3.000 µg/l, 10.000 µg/l and 1.200 µg/l.

Plant installed

The plant installed consisted in a devices of air injection and extraction generated by a blower/aspirator. The air flow allowed the depuration of groundwater and interstitial gas within the ray of action do the plant; here groundwater have been analyzed by 3 monitoring piezometers installed respectively at 5, 15 and 30 m from the SmartStripping well®. the area downline of the hydraulic groundwater flow have been controlled through a specific monitoring carried out directly by the client, and finalized to check the effectiveness of the system.

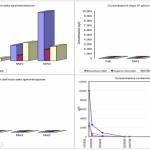

After 3 month of working

After 3 month of working, the SmartStripping® plant removed about 10 kg of organic compounds and after 11 month by the beginning of the field test, the concentration of MTBE decreased to <0,5 ug/l, total hydrocarbons to <10 ug/l and total aromatic organic compounds to <1 ug/l. Monitoring data of the client are in agreement with the field test expectations, given the favorable site-specific conditions, including the high porosity and permeability of soils, the presence of contaminants extremely volatile and low depth to groundwater.

VOC’s reduction

The field test of SmartStripping® technology has permitted a significant reduction in the concentrations of volatile pollutant in groundwater and their extraction from subsoils. Furthermore, with a single SmartStripping® well and in 3 months of activity, have been measured the following environmental benefits: the purification and preservation of approximately 1.000 cubic meters of groundwater, not extracted from the aquifer, the lack of emissions of approximately 120.000 cubic meters of “purified and recycled” gas flowing in the SmartStripping® closed loop, the production of zero kg of waste, since all the used activated carbons have been regenerated and recycle.